Product

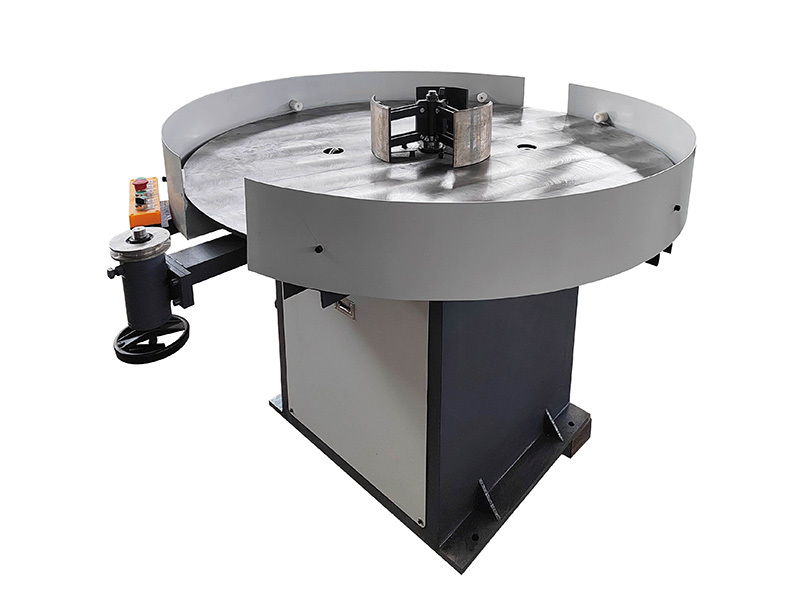

Steel Strip Rewinding Unit

The steel strip rewinding unit is a process of unwinding the raw steel strip from the roll and rewinding it to the I-shaped wheel. The unit is controlled by PLC and the unwinding and take-up motors work together.

Keyword:

Flux Cored Wire Production Line

the

steel

strip

and

Category:

E-mail:

Steel Strip Rewinding Unit

The steel strip rewinding unit is a process of unwinding the raw steel strip from the roll and rewinding it to the I-shaped wheel. The unit is controlled by PLC and the unwinding and take-up motors work together.

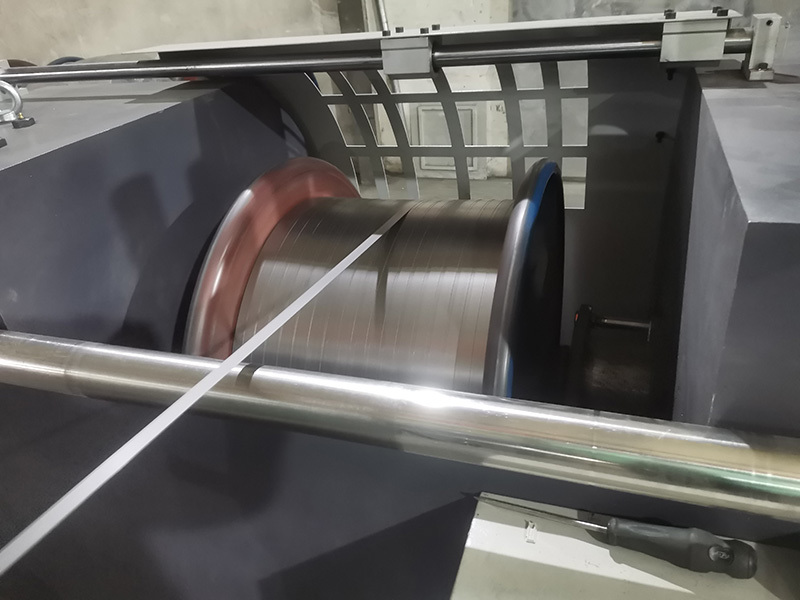

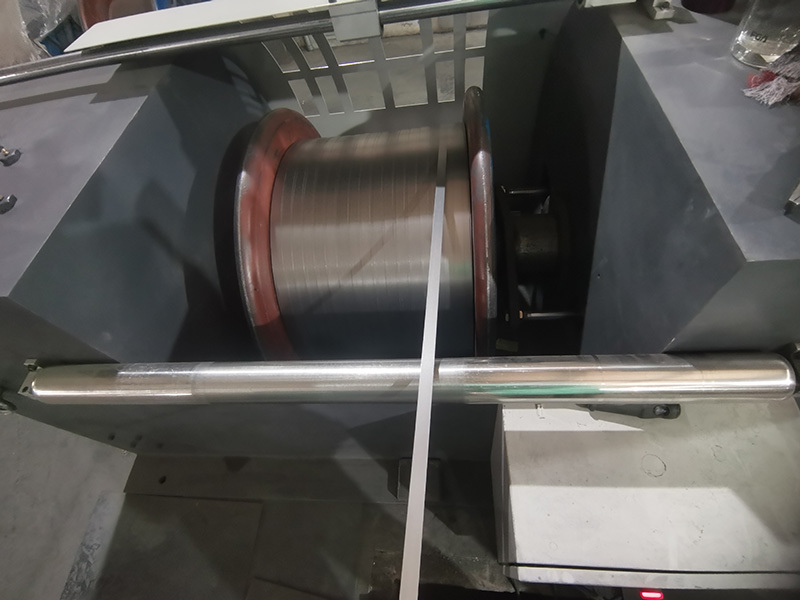

The cable arrangement is driven by a servo motor, and the cable spacing can be adjusted according to different steel strip sizes.

Production parameters

(1) Steel strip specifications: width 8mm-20mm, thickness greater than 0.3mm

(2)Outer diameter of steel strip reel: no more than φ1500mm

(3) Inner diameter of steel strip reel: φ300mm—φ500mm

(4)Production speed: maximum speed 500m/min

(5)Total equipment power: 22.75kw

Tape player

Outstanding advantages

1.The tape unwinding machine detects the remaining amount of steel strip, slows down when the remaining amount is insufficient, and automatically stops when the steel strip is used up.

2.The equipment is capable of stable and high-speed production, with a maximum speed of 500m/min, leading the industry.

3.The cable arrangement is stable, the steel strips are arranged neatly, the take-up cable arranger adopts soft limit, and the left and right reversing positions are digitally controlled through the touch screen, eliminating the need for manual position adjustment of the cable arranger.

Equipment application site

Take-up machine

Electrical Controls And Operating Systems

1.1/0 distributed communication control, that is, sub-station control: maintenance is simplified, equipment on-site construction is shortened, and customers’ time is reduced several times

Flux Cored Wire All In One Machine

Since 2021, the new generation of flux-cored wire integrated machine independently developed by our company has been put into production and use by well-known domestic welding wire companies. The equipment adopts

The steel strip rewinding unit is a process of unwinding the raw steel strip from the roll and rewinding it to the I-shaped wheel. The unit is controlled by PLC and the unwinding and take-up motors work together.

The flux-cored wire post-treatment process is a process of cleaning the surface of the welding wire after the wire is drawn. Reducing the wire drawing powder on the surface of the welding wire will help improve the wire feedability and reduce the diffusible hydrogen content of the deposited metal.

Leave message online